- Research

in the Barron Group

-

-

- Alumina Nanoparticles:

from Sol-Gel to Composites to Hybrid

Materials

- Alumina

sol-gels

- What is an alumina

sol-gel or alumoxane?

- Understanding

Structure

- Developing a Rational

Synthesis

- Alumoxane

Nanoparticles

- Why are carboxylates

ideal ligands?

- Applications of

Carboxylate-Alumoxanes as Ceramic Precursors

- Ceramic Processing

and Composites

- Rational Control

over Ceramic Pore Size

- Chemically Functionalized

Nanoparticles

- Inorganic Organic

Hybrid Materials

- Catalyst

Components

Top of

Page

- Alumina

Sol-Gels

-

- What is an Alumina Sol-Gel or

Alumoxane?

-

- The common solution-gelation route to

aluminum oxides employs aluminum hydroxide or hydroxide-based

material as the solid colloid, the second phase being water and/or

an organic solvent. Aluminum hydroxide gels have traditionally

been prepared by the neutralization of a concentrated aluminum

salt solution; however, the strong interactions of the freshly

precipitated alumina gels with ions from the precursors solutions

makes it difficult to prepare these gels in pure form. To avoid

this complication alumina gels may be prepared from the hydrolysis

of aluminum alkoxides, Al(OR)3.

-

-

- Although this method was originally

reported in 1922, it was not until the 1970's that alumina

aerogels were prepared, and transparent ceramic bodies were

obtained by the pyrolysis of suitable alumina gels, that interest

increased significantly. There have been several efforts to

improve the processing control of sol-gels (including development

of environmentally benign routes), however, we proposed that

without an understanding of the structure of these materials any

further development was limited.

-

- The aluminum based sol-gels formed during

the hydrolysis of aluminum compounds belong to a general class of

compounds: alumoxanes. Alumoxanes were first reported in 1958,

however, have since been prepared with a wide variety of

substituents on aluminum. The structure of alumoxanes

was proposed to consist

of linear or cyclic chains (i.e., analogous to that of

poly-siloxanes).

- Understanding Structure

-

- In order to determine the structure of an

alumina sol-gel we re-investigated the first sol-gel reaction; the

hydrolysis of Al(OSiEt3)3. Using a

combination of 1H, 2H, 13C,

17O, 27Al, and 29Si NMR

spectroscopy and XPS we proposed the structure of the

siloxy-alumoxanes to consist of a Al-O core

whose structure was that of the mineral

boehmite, [Al(O)(OH)] (Chem. Mater., 1992,

4, 167). This was confirmed by the X-ray structural

characterization of

Al10(OH)16(OSiEt3)14.

-

- Top of Page

- Developing a Rational

Synthesis

-

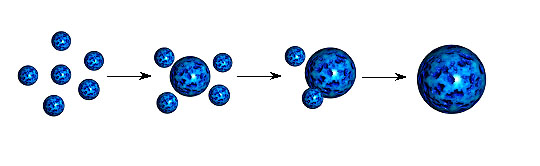

- Precursor sol-gels are traditionally

prepared via the hydrolysis of aluminum compounds. This

"bottom-up" approach of reacting small inorganic molecules to form

oligomeric and polymeric materials has met with varied success,

due to the difficulties in controlling the reaction conditions,

and therefore the stoichiometries, solubility, and processability,

of the resulting gel. It would thus be desirable to prepare

alumoxanes in a one-pot bench-top synthesis from readily

available, and commercially viable, starting materials, which

would provide control over the products. Based on our knowledge of

the boehmite-like core structure of hydrollytically stable

alumoxanes, we posed the following question: Can alumoxanes be

prepared directly from the mineral boehmite? At that time, a

"top-down" approach represented a departure from the traditional

synthetic methodologies.

-

- In the siloxy-alumoxanes we had shown the

"organic" unit itself contains aluminum. Thus, in order to prepare

the siloxy-alumoxane similar to those we have previously reported,

the anionic moiety, the "ligand"

[Al(OH)2(OSiR3)2]-,

would be required as a bridging group; adding this unit would

clearly present a significant synthetic challenge. However, the

carboxylate-alumoxanes represent a more realistic synthetic target

since the carboxylate anion,

[RCO2]-, is an isoelectronic and

structural analog of the organic periphery found in our

siloxy-alumoxanes. Based upon this rational we have developed a

"top-down" approach based upon the reaction of boehmite,

[Al(O)(OH)]n, with carboxylic acids (J.

Mater. Chem., 1995, 5, 331). This synthesis has been

extended to allow for aqueous processing (Chem. Mater.,

1997, 9, 2418).

-

- The carboxylate-alumoxane materials

prepared from the reaction of boehmite and carboxylic acids are

air and water stable materials and are very processable. The

soluble carboxylate-alumoxanes can be dip-coated, spin coated, and

spray-coated onto various substrates. The physical properties of

the alumoxanes are highly dependent on the identity of the alkyl

substituents. The alumoxanes are

indefinitely stable under ambient conditions, and are adaptable to

a wide range of processing techniques. Additional advantages

include: the low price of boehmite and the availability of an

almost infinite range of carboxylic acids.

Top of Page

- Alumoxane Nanoparticles

-

- A detailed study of the

carboxylate-alumoxanes shows them to be aluminum-oxide

nanoparticles whose surface is stabilized by the carboxylate

group. The size of the nanoparticle is dependent on the identity

of the carboxylate and the solution pH (J. Non-Cryst. Solids,

2001, in press).

-

- The majority of our studies use the

following carboxylic acids: acetic (A-H), methoxyacetic (MA-H),

methoxyethoxyacetic (MEA-H), methoxyethoxyethoxyacetic (MEEA-H),

para-hydroxybenzoic (p-HB-H) and lysine (L-H).

-

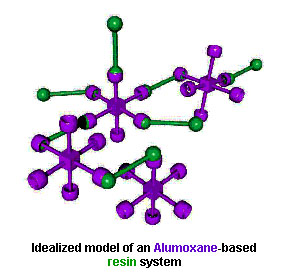

- We have been able to model the

surface of the alumoxane nanoparticles to confirm the mode of

binding of the carboxylate groups

(Organometallics, 1995, 14, 4026).

- Why are carboxylates ideal

ligands?

-

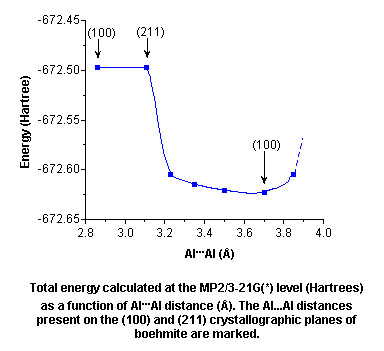

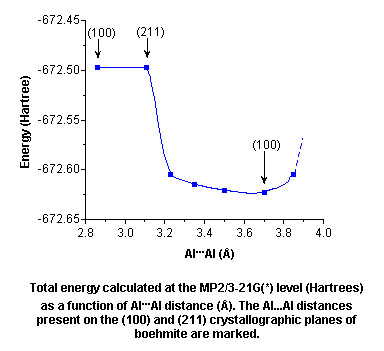

- Using a combination of X-ray

crystallography and ab initio calculations (Organometallics,

1997, 16, 329) we have shown that the carboxylate

ligand is therefore near perfectly suited to bind to the (100)

surface of boehmite (Al...Al = 3.70 Å), and hence

stabilize the boehmite-like core in carboxylate

alumoxanes.

-

- We have extended the principle of

using model compounds to other inorganic surfaces (Polyhedron,

1998, 17, 3121).

-

-

Top

of Page

- Applications of Carboxylate-Alumoxanes

as Ceramic Precursors

-

- Ceramic Processing and

Composites

-

- The carboxylate-alumoxane nanoparticles are

ideally suited to a wide range of ceramic processes. We have

demonstrated examples of the following: use of the alumoxanes as

pre-ceramic binders for low shrinkage green bodies (Chem.

Mater., 1997, 9, 2418); the infiltration and surface

repair of ceramic surfaces; the dip coating of SiC, sapphire,

graphite and Kevlar fibers (J. Mater. Res., 2000,

15, 2228) to be used to simplify the fabrication of

FRCMCs.

-

- Possible applications

of these process improvements are in the automotive and aerospace

industries (World Car Conference '96, University of

California, Riverside, p. 151).

-

- Top of Page

-

- Rational Control over Ceramic Pore

Size

-

- Carboxylate-alumoxanes are converted to

alumina upon thermolysis. The pore size and pore size distribution

is influenced by the selection of the organic substituent on the

nanoparticle surface, while the average pore sizes may be altered

through either physical or chemical mixtures of two (or more)

carboxylate-alumoxanes. Most important is our ability to create

intra-granular porosity of a controlled size (Adv. Mater.,

2000, 12, 734).

-

Top of Page

- Our ability to produce alumina with small

pore size and very narrow pore size distribution has allowed us to

fabricate alumina ultrafiltration membranes derived from

carboxylate&endash;alumoxane nanoparticles (J. Membrane Sci.,

2001, in press). These membranes have a molecular weight

cut-off in the range of 30,000 g.mol-1 and permeability compare

favorably (or are superior to) commercially

available ultra filtration membranes.

-

-

Top of Page

Chemically Functionalized

Nanoparticles

- Given the wide range of carboxylic acids

available with secondary functionalization it is possible to

simply prepare alumina nanaoparticles with

well designed chemical functionalization on the

exterior.

- Inorganic-Organic Hybrid

Materials

-

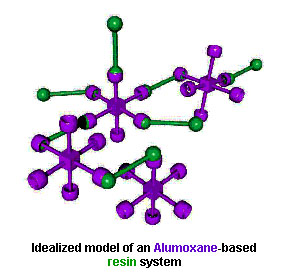

- Chemically functionalized alumina

nanoparticles (carboxylate-alumoxanes) are used as the inorganic

component of a new class of inorganic-organic hybrid materials.

Lysine- or para-hydroxybenzoic acid-derivatized alumoxanes.

The peripheral organic hydroxides and amines of these

carboxylate-alumoxanes either react directly with epoxide resins,

such as the diglycidyl ether of bisphenol-A (DER 332), to form a

hybrid material, or in the presence of an organic resin and

hardener system to form a composite material (Chem. Mater.,

2000, 12, 795). The properties and cure times of the

alumoxane hybrid and composite materials are distinct from both

the pure resins and from a physical blend of the resins with

traditional ceramic fillers. A significant increase in thermal

stability and tensile strength is observed for both the hybrid and

composite resin systems.

-

- The presence of the

alumoxane nanoparticles chemically bound to the resin results in a

drastic improvement in the torsional strength of composites as

well as smaller increases in tensile strength and thermal

stability.

-

- Top of Page

- Catalyst Components

-

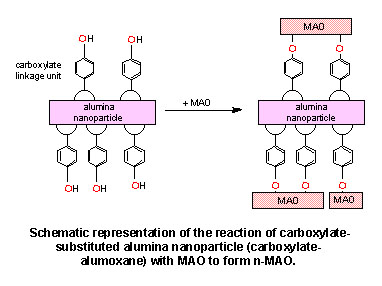

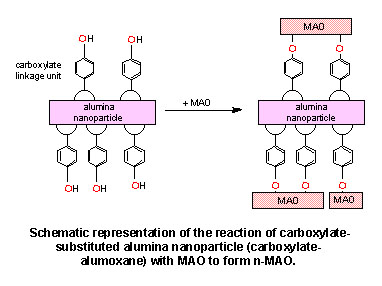

- A new class of metallocene/MAO-based solid

olefin polymerization catalyst has been developed using chemically

functionalized nanoparticles (carboxylate-alumoxanes) as a well

defined substrate. Reaction of para-hydroxybenzoate-alumoxane

(p-HB-A) nanoparticles, formed from the reaction of the

acid with boehmite, with methylalumoxane (MAO) results in a solid

nanoparticle-based MAO (n-MAO) which reacts readily with

zirconocenes, including: Cp2ZrCl2,

Cp2ZrMe2 and

(nBuCp)2ZrCl2, to make an active

solid catalyst for olefin polymerization. The catalytic activity

of the n-MAO based catalyst is greater than the homogeneous analog

under similar Al(MAO):Zr ratio and is comparable to

that of a traditional silica supported catalyst but offers the

potential of being easily chemically modified.

Top

of Page

Return

to Research in the Barron Group

Return

to Barron Group Home Page